Are you a baker who makes their bread and butter producing cookies? The FDA Food Safety Modernization Act (FSMA) Preventative Controls for Human Food requires commercial bakeries to provide validation of process controls such as thermal kill steps.1 Compliance dates for some businesses began in September of 2016. The good news is a new Kill Step Validation Calculator has been created specifically for both soft and crispy cookies.

A group of bakers and researchers came together with the overall objective: to provide bakery manufacturers with a science-based validation tool that can be used to demonstrate the effectiveness of a baking process to destroy Salmonella spp. in a variety of bakery products.3

What does the FSMA require?

In an effort to reduce food borne illness caused by pathogens common in the food industry, the FDA created the FSMA. Although not directly linked to improper processing practices, there were 30 disease outbreaks and 706 illnesses linked to bread products between 1998 and 2007.4

According to the FSMA section 117.160 food facilities need to keep records of the validation of their production process control activities.1 In your bakery the oven is your process control activity. Section 117.160 goes on to say “a thermal kill step above 165º F might only be effective if the production temperature is known to actually reach the minimum temperature of 165º F for a sufficient period, such as 15 seconds. Ensuring the effectiveness of a thermal process control might require a correctly functioning thermometer that is installed, calibrated, monitored and its effectiveness verified with a program of on-going records review by preventive controls qualified individuals, which may include production managers or quality assurance staff.”1

How can bakeries provide validation of an effective thermal kill step?

In cooperation AIB, The University of Georgia, American Bakers Association, and Kansas State University conducted research to confirm the steps necessary to validate baking as a kill step in controlling Salmonella in hamburger buns. The researchers wanted to assure the quality of the baked hamburger bun would remain the same with the validation of the kill step.

A series of preliminary hamburger bun baking trials were carried out at different temperatures and time periods to determine the optimum hamburger bun bake profile simulating the common baking industry practice.4 The buns baked at 218.3°C (425°F) for 13 min in the kitchen oven were found to be optimum, matching the baking industry’s hamburger bun end-use quality parameters such as crust color, appearance, size, texture, and internal crumb temperature.4

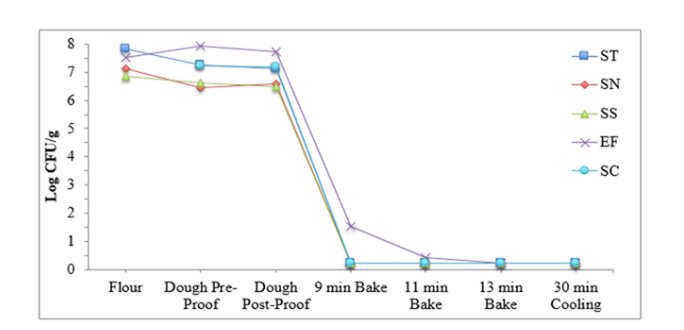

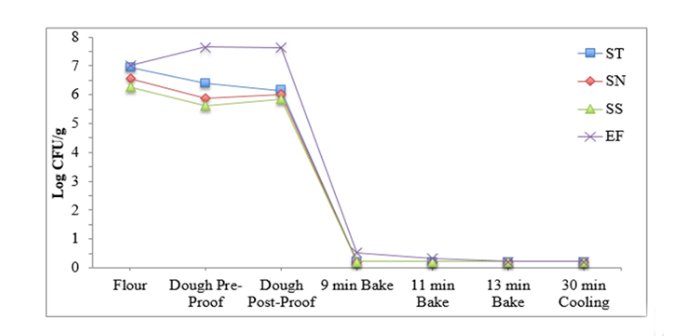

The study demonstrated that the typical hamburger bun baking process will eliminate Salmonella serovar populations (>6-log CFU/g reductions) utilizing oven temperatures ≥218.3°C (425°F) and baking for at least 9 min.4 See figures 1 and 2 below.

Figure 1. Survival population of Salmonella serovars, Enterococcus faecium and Saccharomyces cerevisiae, in hamburger buns during baking at 218°C (using selective media)3,4

Figure 2. Survival population of Salmonella serovars, Enterococcus faecium and Saccharomyces cerevisiae, in hamburger buns during baking at 218°C (using injury recover media)3,4

The research done to determine the time and temperature necessary to kill most common pathogens in hamburger buns resulted in the creation of the Kill Step Calculator. Kill Step Calculators now exist for 8 common bakery products with more on the way.2 If cookies are your concern AIB offers instructions for both pan baked cookies and baking cookies on a travelling band oven.5,6

The simplified steps are:

Step 1: Format the Data Logging Device

Step 2: Placement of Data Logger

Step 3: Data Compilation and Oven Validation

The data compiled can be summarized in reports and kept on file in order to comply with the required validation of processes controls for the FSMA.1

Using the Cookie Kill Step Calculator will bring your bakery into compliance with the Food Safety Modernization Act. This tool allows bakers to monitor, validate and record critical control points in the bakery. Knowing your ovens are functioning properly for perfectly baked cookies assures your customers are happy and safe.

References

- FDA. “Part 117 FSMA Final Rulemaking for Current Good Manufacturing Practice and Hazard Analysis and Risk-Based Preventive Controls for Human Food.” www.fda.gov/downloads/AboutFDA/ReportsManualsForms/Reports/EconomicAnalyses/UCM472884.pdf. Accessed 01 March 2017

- “Baking Process Kill Step Calculators – Empowering Bakeries to Validate Their Food Safety Preventive Controls.” AIB International. AIB, 4 Nov. 2016. www.aibonline.org/aibOnline/develop-your-product-solutions/baking-process-kill-step-calculators.aspx. Accessed 02 March 2017.

- Channaiah, Kantha “Kill-Step Validation of the Baking Process to Comply with FSMA Rule.” IBIE2016. PowerPoint file.

- Lakshmikantha H. Channaiah, Elizabeth S. Holmgren, Minto Michael, Nicholas J. Sevart, Donka Milke, Carla L. Schwan, Matthew Krug, Amanda Wilder, Randall K. Phebus, Harshavardhan Thippareddi, and George Milliken (2016) “Validation of Baking To Control Salmonella Serovars in Hamburger Bun Manufacturing, and Evaluation of Enterococcus faecium ATCC 8459 and Saccharomyces cerevisiae as Nonpathogenic Surrogate Indicators.” Journal of Food Protection: April 2016, Vol. 79, No. 4, pp. 544-552. doi: http://dx.doi.org/10.4315/0362-028X.JFP-15-241